Palletising Solutions

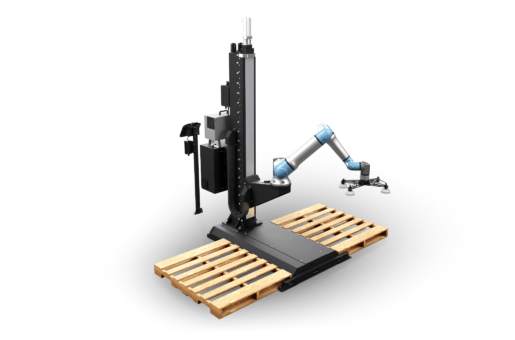

Cobot Palletising Solutions Range from Robotiq

Palletising can be a repetitive and strenuous task when handled manually, so it is one of the most common robotic solutions used by manufacturers. Robotiq offers lean palletising solutions, enabling simple, rapid automation. Their standard PE Series and AX Series palletising solutions can do the heavy lifting for you, while remaining safe for employees to be around.

Making the automation process as straightforward as possible, Robotiq offers PAL Ready and PAL Series: two paths to simple, straightforward palletising automation. You can choose between the off-the-shelf PAL Ready palletiser, or the modular PAL Series approach, allowing you to customise the solution to suit your needs.

The benefits of the Robotiq automated palletising solutions:

- Flexibility – palletising robots can handle a wide range of box sizes, shapes, weights, packaging materials, adapting to frequent changes of box dimensions

- Efficiency – the software optimises trajectories to maximize speed & payload capacity and achieve the highest throughput

- Easy set up – the intuitive interface and intelligent software make it easy for anyone to operate, regardless of your robotics knowledge

- Compact – the small footprint means the palletiser fits easily within your existing floor space making installation easy

Most significantly, Robotiq include the software and all updates as part of the solution, and there are no annual licence fees to pay.

Robotiq’s cobot palletising can be easily integrated alongside your existing manufacturing lines, making automated palletising, depalletising, or both, a perfect solution to enhance your end-of-line operations.